Even the most expensive and high-quality knife once loses its original sharpness and requires sharpening. You can return the lost sharpness to the instrument on your own at home, but you will have to consider several nuances. It is not enough to move the blade over the whetstone. If you sharpen it incorrectly, you risk ruining the cutting edge or dulling it even more. Before starting work, it is essential to determine the correct sharpening angle of the knife and observe it during all manipulations to sharpen the blade.

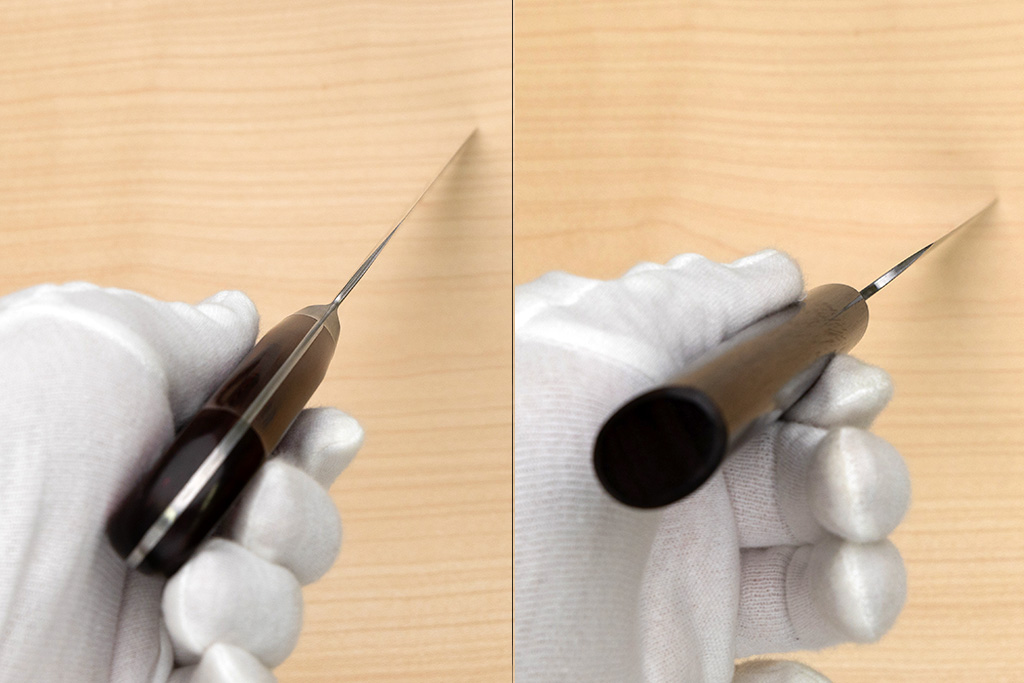

You don't need to be a great physicist to understand that the thinner the cutting edge of a knife, the higher its cutting ability, the more convenient it is to work with a knife. The design features of the knives are such that the smaller the angle between the arches of the blade, the smaller the area of contact with the product. When planning to determine the correct sharpening angle of a kitchen knife, you need to assess the degree of convergence of the inlets. These are the areas of the blade where the downsides of the knife merge into the cutting edge.

The angle of sharpening of kitchen knives cannot be universal. It depends on:

- the purpose of the knife;

- type of steel (the largest angle is for ceramics, the minimum is for Japanese blades);

- the blade is sharpened on one or both sides;

- design features of the blade.

The origin of the knife may also matter. So, the Japanese produce blades with one-sided blade sharpening at a minimum angle, up to 15 degrees. Europeans are not inclined to such a filigree cutting edge processing; therefore, they are often limited to 30 degrees. Japanese brands also produce Europeanized models with a classic double-sided sharpening, but they are true to themselves to make the sharpest and highest quality tool possible. Therefore, even such models have a minimum sharpening angle of 15-25 degrees.

In addition, the "Japanese" have ideally straight sides of the cutting edge triangle when viewed from the end. Perfect geometry is achieved through the use of manual labor for the final sharpening. For "Europeans," the sides of the triangle are concave since the sharpening is done automatically. This indicator affects the quality of the cut and the service life of the knife. The concave cutting edge grinds off faster, and the knife has to be replaced with a new one.

A large sharpening angle is for ceramic knives. This material is very brittle, so manufacturers usually sharpen the cutting edge at a 40-degree angle. It does not affect cutting properties as the blade is very hard and hardened at extremely high temperatures and then sharpened on diamond stones.

WHAT IS THE CORRECT ANGLE FOR KNIFE SHARPENING

In time, it is worth knowing the angle of sharpening of a new product, which the manufacturer sets. During the operation of the knife, the angle may change, and it will be problematic to guess what it was before. You can determine the sharpening angles of different blades in the following ways:

- With scissors. The scissor blades should be opened as much as possible. Install the cutting edge of the knife in the joint. Close the scissor blades, fixing this distance. Attach the corner to the paper and trace with a pencil. Measure the drawn corner with a protractor.

- With a candle. It is necessary to light a candle and pour the melted wax onto a horizontal surface with a layer of 0.5-1 cm. Stick a knife blade into warm wax and leave until the mass hardens. Pull out the blade, photograph the resulting hole and measure the angle in the photograph using a protractor.

- Using a protractor. This is a special technical device that determines the angle of a particular product. However, such a tool is quite specific and is not available in every home.

- Ask the manufacturer. Suppose you have a professional knife of a well-known brand. In that case, you can find out the initial sharpening angle of a particular model from an official representative of the brand or a seller.

STANDARD SHARPENING ANGLES

If you cannot determine the knife sharpening angle, you can follow generally accepted recommendations. There is a table where it is indicated which knife sharpening angle is best for tools, depending on the purpose:

- table knife 55 ° - 60 °(grinding angle)

- kitchen household knife 30 ° - 35 °

- professional kitchen knife 25 ° - 30 °

- professional chef knife 20 ° - 25 °

- knife for cutting fish 25 °

- knife for cutting meat 30 °

- knife for cutting vegetables 35 °

- knife for cutting root vegetables 22 ° - 25 °

- knife for boning, for separating meat from bones 25 ° - 30 °

- to separate the sirloin 10 ° - 15 °

- for frozen products of animal origin 30 ° - 45 °

- pocket knife 20 ° - 25 °

- tourist / hunting, priority - sharpness 30 ° - 35 °

- tourist / hunting, priority - wear resistance 40 ° - 45 °

- shoe repair knife 30 ° - 40 °

- shoe cutting knife 20 ° - 25 °

- universal carpentry knife 30 ° - 45 °

Once you understand the angle of the cutting edge should be, it is worth thinking about how you plan to maintain it when sharpening the tool. Experienced craftsmen set the knife in the correct position relative to the sharpening bar by eye, guided by honed dexterity. An inexperienced user may need a knife sharpening guide - an angle holder. This device allows you to fix the blade relative to the sharpening tool in the desired position. It is attached to the butt of a knife. Automatic and electric sharpeners may have a built-in angle holder adjusted from 15 to 45 degrees.

The ideal knife sharpening angle corresponds to the purpose of the tool and its design features. With the correct sharpening of the blade at the right angle, the tool regains the lost sharpness and again becomes a functional assistant to the cook.

POST COMMENTS

0 COMMENT(S)