Japanese Knives Types

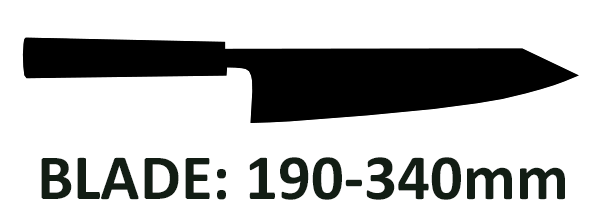

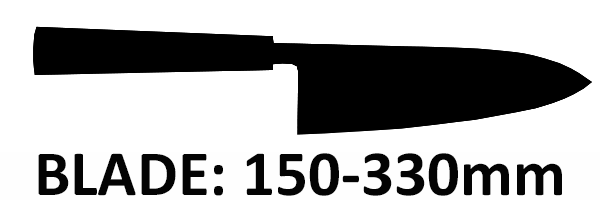

Western-style or so-called Modern Japanese knives appeared in Japan after 1868 (Meiji Period) under a significant western influence in their design. But, despite the external resemblance, Japanese knives are much lighter and thinner than European knives. Also, Japanese knives are sharper, have higher blade steel hardness, and have better balance. For Japanese blacksmiths in knife making, it has always been the priority to achieve just the perfect knife cutting quality. And this is not surprising, given that the history of kitchen knife production in Japan started with the combat swords making.

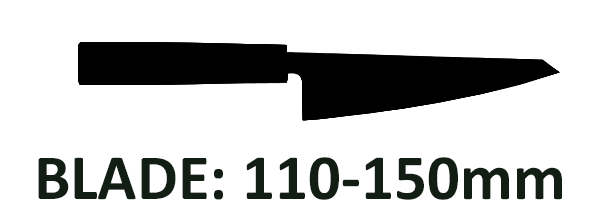

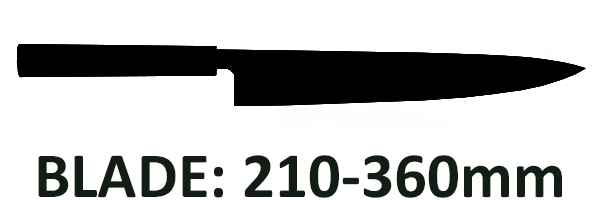

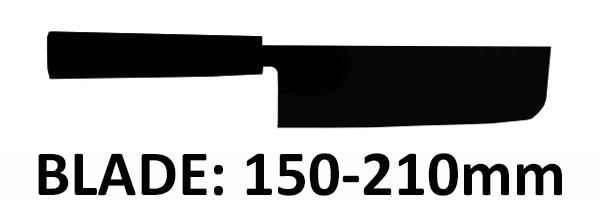

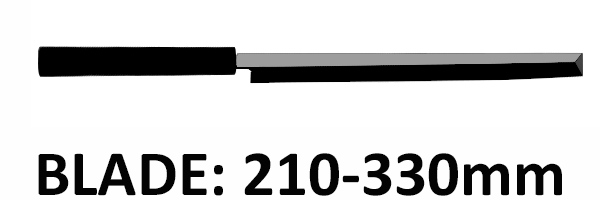

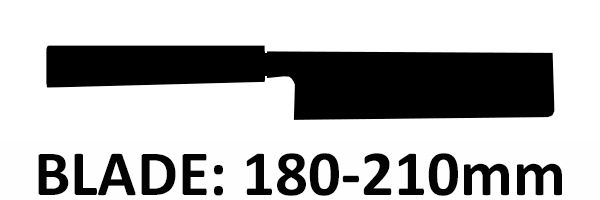

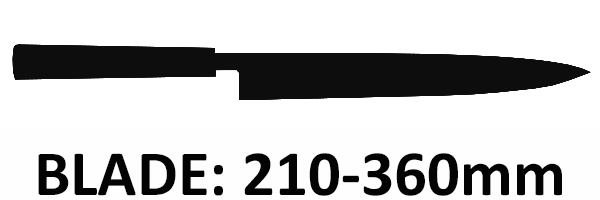

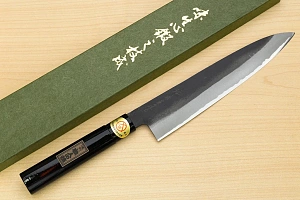

Traditional Japanese knives differ considerably from others by their unique shapes, single-bevel edge, and incredible sharpness. Moreover, each knife shape has a particular name and is strictly specialized for cutting the exact product. Yanagiba knife is for slicing raw Fish for Sushi or Sashimi; the Deba knife is for fish dismantling; for peeling and cutting vegetables - Usuba. The history of traditional Japanese knives' starts in the Edo period (around 1603 -1867). At that time, all Japanese chefs were strictly divided and specialized by the products. Chefs who cut (kook) fish and meat were called Hochonin, and those who cut vegetables were called Kizami Sakanashi. Since ancient times, Japanese society has been ruled by the concept of perfectionism. Especially noticeable when looking at the masterpieces of Japanese cuisine. To pursue perfection in cooking the products of their specialization, chefs had to order unique, custom knife shapes from the best Japanese blacksmiths (Katana swordsmiths). Of course, knife sharpness was one of the most critical factors that directly depended on steel quality, forging, and sharpening techniques. High carbon steel with a higher Rockwell hardness provides superior edge sharpness and edge retention. But, it was rare and expensive, so swordsmiths had to invent unique forging methods where expensive steel was used only for the cutting edge (Kobuse, Sanmai, etc.) To prevent cutting edge melting down through the heat up during the sharpening, they also had to invent the whetstones and unique sharpening technique. In the process of frequent sharpening, it became clear that a single angle is much more comfortable for sharpening than a double bevel and gives a better, incredibly thin cutting edge. Naturally, step by step, each subsequent knife becomes better and better. And as a result, after hundreds of years, Japanese traditional knives have become highly specialized, ultimate kitchen tools, the quintessence of the best forging technology, materials, and practical design and sharpening methods.