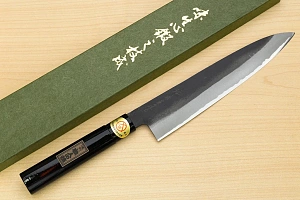

Japanese Carbon Steel Knives

Carbon steel, from the title, contains a large amount of carbon (high-carbon steel) in its composition (from 0.6% to 2.0%). It is carbon that gives the blade excellent strength and wears resistance, allowing it to maintain the sharpness of the blade edge for a long time, even with active use. Going a little deeper into history, you can see that until the beginning of the 20th century, all over the world, only high carbon steel was used for the production of kitchen knives. In 1914 the George Ibberson & Co., from Sheffield, England, started making a knife from stainless steel. But their knives soon earned the reputation of "Knife that not cut." Of course, modern stainless steel doesn't have such a problem. But why do Japanese professional chefs and Japanese steelmakers (Hitachi Metals, etc.) still prefer carbon steel despite its tendency to rust? The main reason is the possibility of carbon steel sharpening to an extremely high level of sharpness and long-term retention of the cutting edge at its relatively low price. Stainless steel with the same cutting spec will be more expensive.

In Japan, Sharpness, or rather, the ability of a knife to make a perfect cut, is especially important. One of the essential Japanese Cuisine) Principles (和食, Washoku) is "Eating" with eyes. It means that Japanese food should be fascinated with freshness, looks, colors, shapes, textures, and design. So, every slice cut should be done perfectly, without smashing the product. Fresh looks (HIKARI-shining) of Sashimi or Sushi (sliced raw fish) directly depend on the knife's sharpness.

Conclusion:

If you often use a knife, and quality cuts and clean slicing are important, carbon steel is the best choice for a relatively low budget. Rusting, we mean an aggressive form with an orange flaky carbon steel surface, is easily avoided by wiping the knife to remove moisture. But you should be prepared that the knife blade will receive a charcoal gray patina anyway in the process of work. But this is not rust. It is a patina, kind of a mild form of oxidation, affects only the outer surface of the blade, and prevents further corrosion. And this patina has an excellent look. If you are not a big fan of patina, you can check blades with a SAN MAI or so-called sandwich construction (stainless clad carbon).